Share

- Product Details

-

Operating Principle:

Under normal operating conditions, both the exhaust and intake valve disc assemblies remain closed to seal the steam. When internal tank pressure increases, the exhaust valve disc opens to release steam and relieve pressure. When the tank experiences vacuum accumulation, the intake valve disc opens to release the vacuum.

Applications:

• Large oil depot storage and transportation centers

• Chemical plant liquid raw material storage areas

• Large-scale gas storage facilities

• Gas cabinets

• Distillation units

• Low-pressure gas pipeline systems

• Port terminal storage and transportation systemsConstruction Materials:

Components

Materials

Other Materials

Housing

Corrosion-resistanthigh-strength non-metal

Aluminum alloy

Carbon steel

304 stainless steel

316L stainless steel

Hastelloy alloy

Valve Disc/Base

Hastelloy alloy

304 stainless steel

316L stainless steel

Hastelloy alloy

(customizable upon customer request)

Valve Diaphragm

FEPTeflon

Nitrile rubber

Fluorocarbon rubber

Cover

Aluminum

Carbon steel

304 stainless steel

316L stainless steel

Counterweight and Spring

Lead

Galvanized carbon steel

Austenitic stainless steel

Coated steel counterweights

Hastelloy alloy

Note 1:Replacement and maintenance of the valve disc, counterweight, and spring should be carried out by personnel dispatched by the manufacturer or under remote guidance from the manufacturer.

Valve Installation Range

Model

Inlet Connection Size

mm/in.

Pressure

KPa(G)

Vacuum

KPa(G)

Model 7310

Counterweight-loaded

DN50~DN300/(2"~12")

0.2~6.9

-0.2~-4.3

Model 7320

Vacuum spring-loaded

DN50~DN300/(2"~12")

0.2~6.9

-4.3~-82

Model 7330

High pressure spring-loaded

DN50~DN300/(2"~12")

6.9~103.4

-0.2~-4.3

Model 7340

High performance spring-loaded

DN50~DN300/(2"~12")

6.9~103.4

-4.3~-82

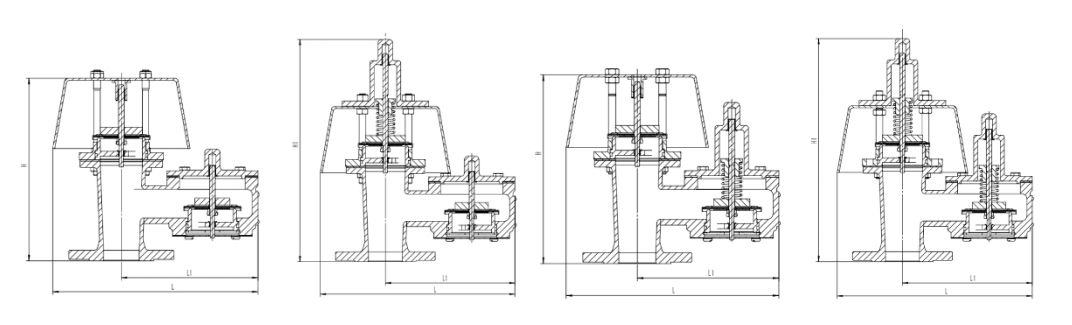

7300 Series Model 7310/7330 End-of-Line Pressure/Vacuum Valve Size Chart

Model

Size

Dimensions

Connection Bolts

Inlet Connection Size

in.(mm)

Total Height

H(mm)

Total Width

W(mm)

Center Width

W1(mm)

Hole

QTY

Thread

Type

7310

/

7330

2"

2"(DN50)

346/405

410

281

4

M16

3"

3"(DN80)

370/435

410

281

4

M16

4"

4"(DN100)

465/545

580

400

8

M16

6"

6"(DN150)

530/590

590

410

8

M20

8"

8"(DN200)

615/680

928

632

8

M20

10"

10"(DN250)

675/715

928

432

12

M24

12"

12"(DN300)

775/855

992

700

12

M24

7300 Series Model 7320/7340 End-of-Line Pressure/Vacuum Valve Size Chart

Model

Size

Dimensions

Connection Bolts

Inlet Connection Size

in.(mm)

Total Height

H(mm)

Total Width

W(mm)

Center Width

W1(mm)

Hole

QTY

Thread

Type

7320

/

7340

2"

2"(DN50)

346/405

410

281

4

M16

3"

3"(DN80)

370/435

410

281

4

M16

4"

4"(DN100)

465/545

580

400

8

M16

6"

6"(DN150)

530/590

590

410

8

M20

8"

8"(DN200)

615/680

928

632

8

M20

10"

10"(DN250)

675/715

928

432

12

M24

12"

12"(DN300)

775/855

992

700

12

M24

※ The actual product dimensions may vary from those listed in the table above. The allowable tolerance is ±1" (25mm). For products with dimensions beyond those listed in the table, please contact the manufacturer for further assistance.

Product application field

Pharmaceuticals

Metallurgy

Food Processing

Petrochemical

Coal Energy

Environmental Protection

Chemical

Electricity

Related Products

Our advantage

Trusted Partner

The company's business also covers the third-level professional contracting of construction mechanical and electrical installation engineering, which can provide customers with one-stop service for product development and design, manufacturing, installation and construction, and after-sales guidance.

Perfect quality system

The company has established a perfect quality management system in strict accordance with domestic and foreign industry standards. China Taian Branch cooperates closely with universities and research institutes to jointly promote technological innovation.

24-hour professional service

With professional after-sales and sincere service as the criterion, 24 hours a day, all year round to provide customers with better quality and more professional service.

Model 7300 End-of-Line Pressure/Vacuum Valve

Parameter characteristics

Applicable sizes: 2" (DN50) to 12" (DN300)

Precision sliding rail design ensures timely valve disc opening and reduces wear

Use of advanced high-performance special materials for key components

Precision spring-loaded components

Valve disc and base are calibrated according to API 2000 standards for optimal performance

Advanced testing platform provides reliable flow rate curves and leakage detection reports

Modular valve body components design for easy and simple maintenance

FEP coating

Optional design for intake (vacuum) port connection

Keywords