Share

- Product Details

-

Application

With the development of modern industry, the potential danger of dust explosions has significantly increased.

Explosion isolation technology can prevent the propagation of explosions from the initial location to other process units, avoiding "secondary explosions" or systemic explosion accidents, and thereby mitigating the damage caused by explosions.

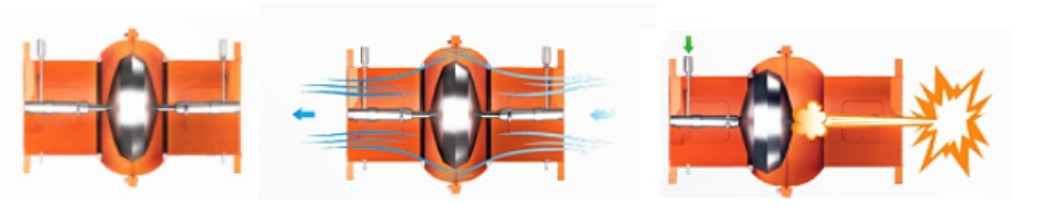

1. When there is no airflow, the closing device is in the open state.

2. During normal operation, airflow passes around the switching device.

3. In the event of an explosion, the device is closed by the impact of the pressure wave, and the sealed valve effectively prevents the propagation of flame or pressure.

Product application field

Pharmaceuticals

Metallurgy

Food Processing

Petrochemical

Coal Energy

Environmental Protection

Chemical

Electricity

Related Products

Our advantage

Trusted Partner

The company's business also covers the third-level professional contracting of construction mechanical and electrical installation engineering, which can provide customers with one-stop service for product development and design, manufacturing, installation and construction, and after-sales guidance.

Perfect quality system

The company has established a perfect quality management system in strict accordance with domestic and foreign industry standards. China Taian Branch cooperates closely with universities and research institutes to jointly promote technological innovation.

24-hour professional service

With professional after-sales and sincere service as the criterion, 24 hours a day, all year round to provide customers with better quality and more professional service.

Active Explosion Isolation Flap Valves

Parameter characteristics

Smooth internal surface for minimal pressure loss.

Rapid reset capability.

Can be installed horizontally or vertically.

For organic dust, Kst can reach up to 400 bar·m/s.

For metal dust, Kst can reach 400 to 450 bar·m/s.

Material: Carbon steel, stainless steel.

Pmax: 13barg.

Keywords